“申龙”船(舰)用轴承加工、安装、使用须知:

INSTRUCTION OF USING, PROCESS AND ASSEMBLY FOR “SL” MARINE BEARING

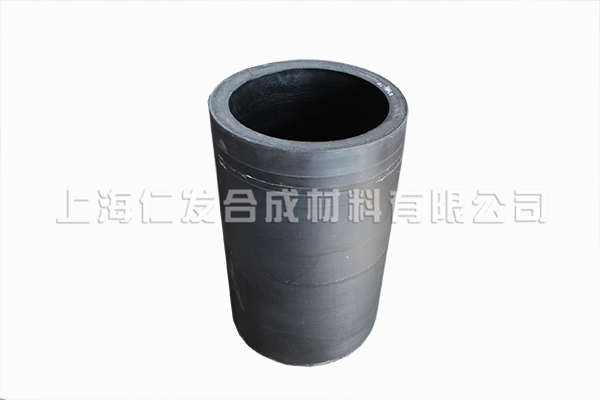

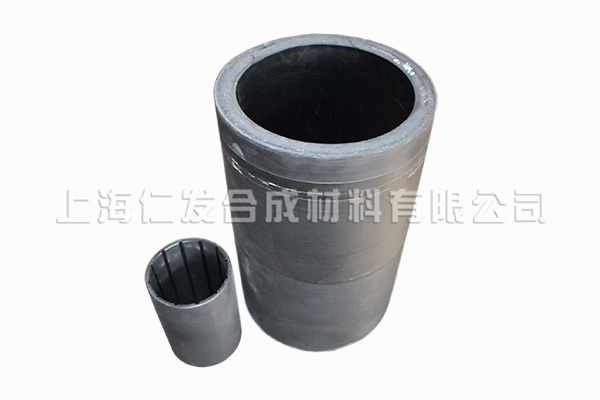

轴承的加工与测量MEASURING & MACHING BEARING

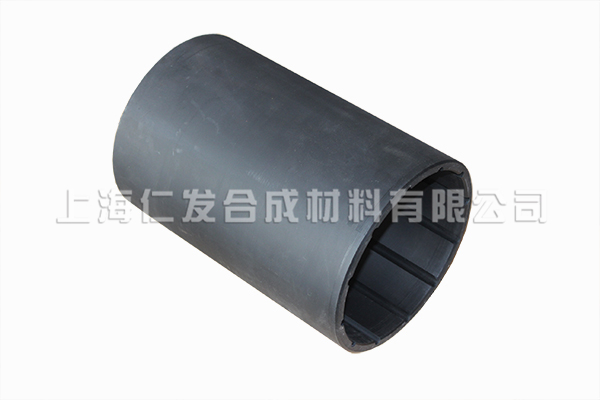

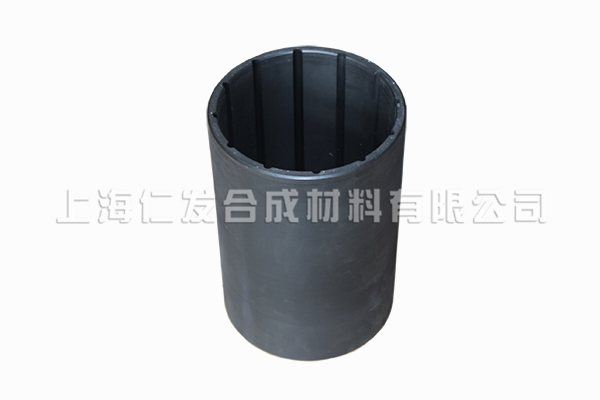

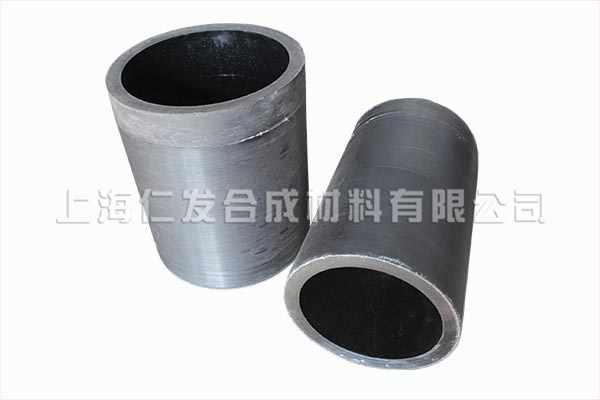

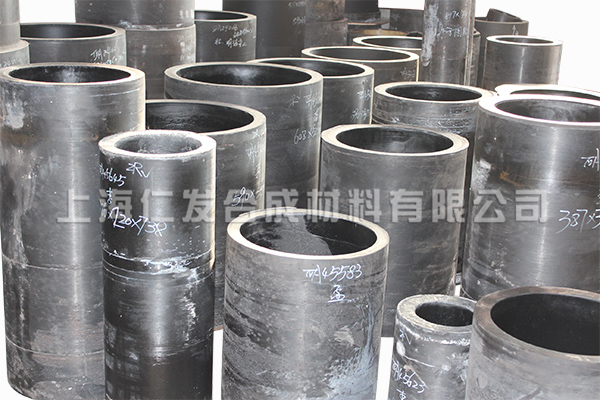

“申龙”轴承是一种坚韧的热塑性聚合物产品,很容易加工。可车、钻、刨、锯、铣等,但不能被磨光。要加工好轴承,应注意以下几点:

1、由于材料质地软并具有一定的弹性,为尽量减小变形,一般在车床夹紧端内孔安装金属衬圈(也可在端面用螺栓或压板固定在机床花盘上加工)。

2、加工好轴承,正确使用刀具很关键,车刀前角、后角应稍大,使切屑从表面容易剥离。车刀要锋利,通常选用硬质合金刀头。

3、要控制适当的转速和进刀量,车速以线速度1.3~1.8米/秒为宜,为获得理想的尺寸和表面加工效果,最后一刀的进刀量在0.25~0.5mm,刀口要尽量锋利。

4、加工步骤:

1)、在轴承一端内孔配一金属衬圈。

2)、车床卡钳夹住衬圈一端,以轴承外圆校对中心,加工外径、内径。

3)、艉轴承必须加工水槽(舵轴承不需要),加工水(油)槽,通常用成形刀头多次拉槽,每次进刀量不能太大,否则容易崩裂。

4)、水槽加工完毕后,切割轴承长度。

5、测量

根据加工实际温度,测量轴承的内、外径。以符合图纸的要求。

由于装夹等原因,下车床后的轴承可能发生椭圆现象,超出公差范围,但压入壳体后它会顺应壳体的形状,恢复圆形。6、“申龙”材料是非金属材料,它不能被加工到金属材料那样紧的公差,由于其特性,可在比金属低的表面光洁度下获得理想的运行效果。

“SL” bearing is a tough thermoplastic polymer composite product, it is easy to machine. The material can be machined by lathe, driller, planer, saw, miller and etc., but it couldn't be ground. Please note the following points for machining the bearing in good condition.

1 .The metal washer must be fit in way of inner hole of the lathe clamp end for reducing the deformation as much as possible because the material is soft and possess certain elasticity, (also can fit end side on the fixing plate of lathe with bolts or clamp plate then machine)

2.It is very crucial to correct use tool for machining bearing in good condition, the front angle and back angle of tool bit should be a little bigger, to make the chip easily detached from surface. The turning tool must be sharp and usually use carbide tip.

3.The speed and amount of feed should be properly controled, The suitable turning speed in linear velocity is 1.3 ~1.8m/s. The amount of feed for last process is in 0.25 ~0.5mm and the tool must be sharp as much as possible for obtaining the ideal dimension.

4.machining process:

1)Fit a metal liner for inner hole in way of one end of bearing.

2)Clamp one end of liner on lathe; align the center as the bearing excircle, machine outer diameter and the bore.

3)Water channel must be machine by miller for stern tube bearing (unnecessary for rudder bearing),to mill water (oil) channel usually by shaped tool tip with more times. The amount of feed couldn't be too much for each time otherwise it will be crack easily.

4)Cut the bearing length after finishing the water channel.

5.measurement

To measure outer diameter & bore of bearing according the maching actual temperature as sketch requirements.

The oval may be occurred for machined bearing after remove from lathe and out of the tolerance, it will be recovered to round after shrink-fit shell body with coordination.6.“SL” material is nonmetallic material, it couldn't be machined too tightening same as metal. Due to its characteristics, the ideal running effect will be achieved under its surface finish is lower than metal.