轴承的安装要求 REQUIREMENTS OF ASSEMBLING BEARING

“申龙”轴承材料有较高的热胀冷缩系数。冷缩是安装最容易的方法。

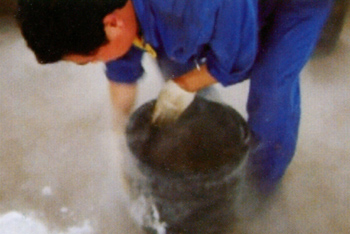

1、用干冰作冷冻剂,可保证冷缩效果。如有专门保温设备和操作经验,也可用液氮冷缩安装。

2、将产品置于一个保温好的圆形容器内,为节省干冰,可在产品中心部位放一空桶(如油漆桶等)。但要保证 产品内、外部有一定空间(单边50mm),将干冰注入容器中,并用木棍夯实,顶部应有干冰覆盖。容器外 面要保温。

3、一般冷冻二至三小时左右,安装前应检查测量轴承外径,是否冷缩到位(一般应比轴承座内孔小0.5~1mm) 否则应继续冷冻。

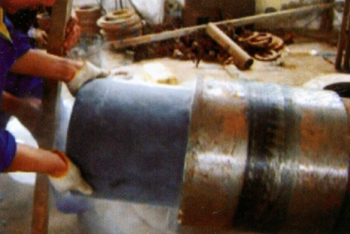

4、安装前应清洁轴承外壳内壁,不能有毛刺或突出物,无须涂润滑油。

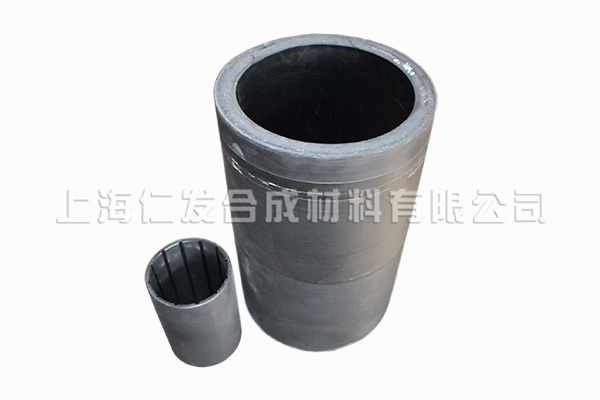

5、安装时要将轴承对准轴承壳,然后小心将轴承推入,中途不要停顿,两端应有一定间隙,以防止轴承吸水后 伸长,顶死挡板而拱起。

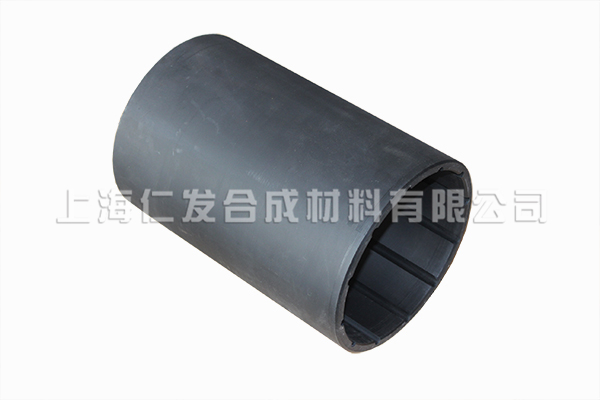

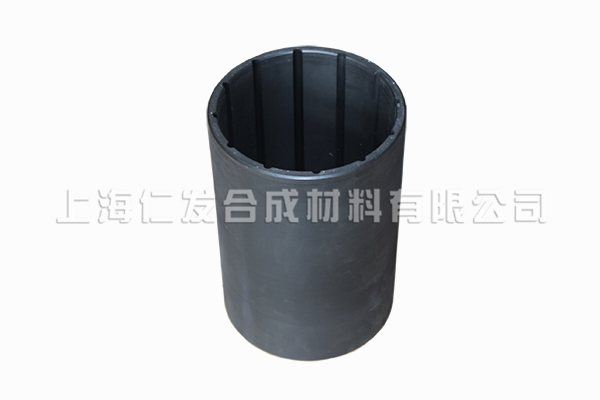

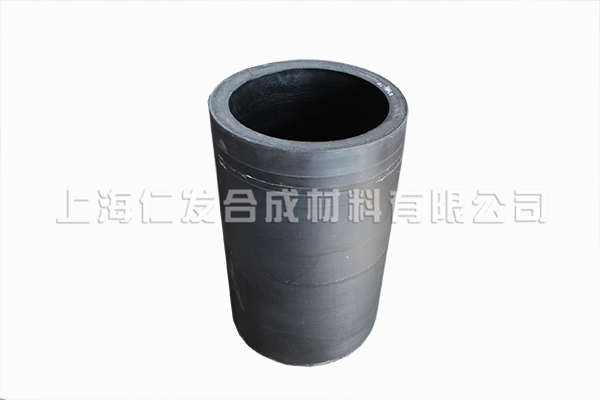

6、艉轴承允许多节安装、但必须保证水在水槽中畅通,以便冷却和润滑轴承。

7、轴承安装后,不得在靠近轴承处进行有可能使轴承变形、烧坏、碎裂的切割、及焊接等作业。

“SL” material has higher heat expands & cold contracts factor. The shrink-fit is a best method for assembly.

1.To use dry ice as coolant, the shrink-fit effects can be ensured. Also the liquid-nitrogen can be used for shrink-fit if you have special heat preserving equipment with operating experience.

2.Put products into a good heat-retaining container, a barrel (paint barrel) can be placed in center of products for save dry ice. But the space (50mm for one side) must be ensured inside & outside of products, then put dry ice into container and tamp with wood bar, cover top side with dry ice. To insulate container outside.

3.Generally freeze for 2 to 3 hours about, before assembly the outer diameter of bearing must be measured and checked whether the shrink-fit is completed or not. Otherwise continue freezing. ( generally less 0.5 ~1 mm) than the inner hole of bearing seating)

4.To cleaned outer shell and in wall of bearing before assembly without any burr or anything on surface and it is unnecessary to coat with lubricating oil.

5.The bearing will be directed at bearing shell when assembly, then carefully push the bearing continuously with out a break. There are some clearance for both ends to prevent bearing extension after sucking in water and avoid the baffle plate arched by supporting.

6.Allow the stern bearing to be assembled with multi-sections, but must ensure the water in channel free for cooling and lubricating bearing.

7.Welding,cutting and any works around bearing area which will make it broken and deformed couldn't be done.

安装方法演示