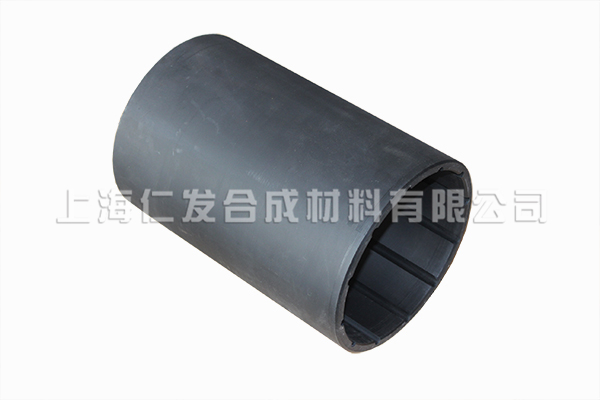

轴承的使用要求 USING REQUIREMENTS FOR BEARING

1、“申龙”轴承安装后,运行时不需要专门维护。

2、艉轴承的冷却水系统应与主机缸套冷却水并联,进水管与轴承套接头位置要安装合理,保证水流畅通。舵轴 承无须强制水冷却或油冷却。

3、冷却水量除保证流量外,还应有一定压力以克服水流通道及船舶吃水深度的阻力,一般为2kg/cm²左右。

4、冷却水阀应常开,并防止水管结垢及异物堵塞。

5、凡安装带气囊艉轴密封装置,注意检查充气阀是否漏气,气囊应设置一常通阀门,以避免气囊充气抱轴使冷 却水不能通过。

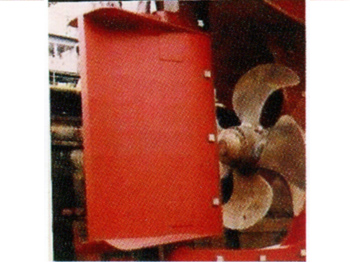

6、艉轴通常应安装防渔网装置,以防止渔网类杂物卷入轴承套内。

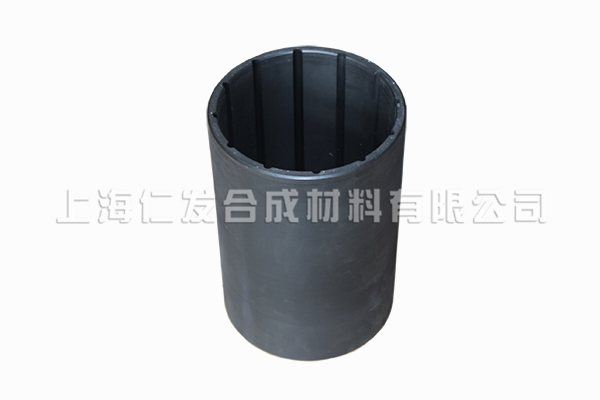

7、轴承压盖凸缘不应紧压轴承端面,一般应留有轴承总长度1%的水膨胀间隙。

1.It is unnecessary to specially maintain “SL” bearing during running after assembling.

2.The cooling water system of stern bearing must be parallel-connected with M/E jacket cooling water. The connecting location for inlet pipe with bearing sleeve joint must be correctly to make sure current is expedite, no compulsory water & oil cooling is necessary for rudder bearing.

3.Ensure the discharge of cooling water and also the pressure to overcome the water current & draft-depth resistance, usually 2kg/cm2 about.

4.The cooling water valve must be always opened to prevent water pipe scaled and clogged.

5.Whatever install the sealing device of tail shaft with air bag, it should be noted to check inflation valve leaked or not. A valve gate must be fit for air bag_so as to avoid seizing shaft by air bag and cooling water can not be through.

6.Generally the fish-net device must be fit for tail shaft to prevent sundries resembled fish net will be into bearing sleeve.

7.The bearing gland flange shouldn't press end side of bearing, usually remain 1% water expansion clearance of overall length of bearing.